The mining industry is standing on the threshold of a digital revolution. As global demand for raw materials surges to fuel the green energy transition and high-tech manufacturing, the European research project MASTERMINE is leading the charge to bring mining into the era of Industry 4.0. By integrating cutting-edge AI, high-fidelity sensors, and autonomous robotics, MASTERMINE is not just updating old systems—it is restructuring the very DNA of mining operations across six strategic axes:

- CYBERMINE: Driving full digital transformation.

- AUTOMINE: Implementing autonomous and electric operations.

- GEOMINE: Ensuring safety and stability in critical structures.

- GREENMINE: Prioritizing environmental sustainability.

- METAMINE: Creating high-fidelity virtual “Digital Twins” of mines.

- OURMINE: Strengthening community engagement and transparency.

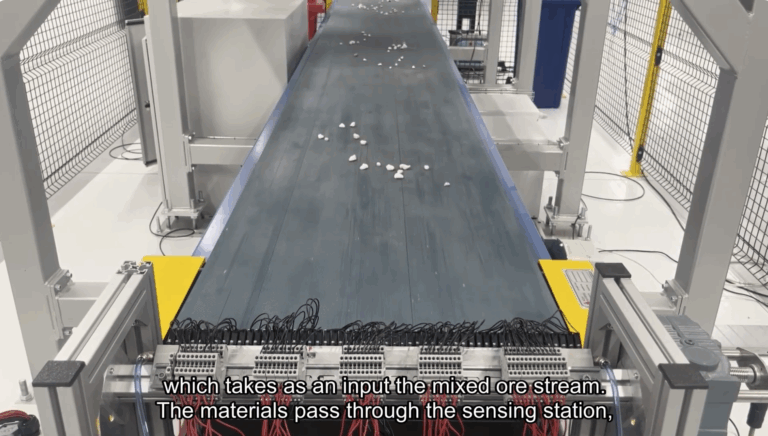

A central highlight of the project’s success is the development of an Autonomous Sorting System, designed and constructed by I-SENSE Group of ICCS.

While modern technology increases the demand for minerals, it also provides the tools to extract them more efficiently. The I-SENSE Group has addressed this by creating a system that removes the need for manual human intervention in the hazardous and labor-intensive mineral sorting process. To showcase how these “Mine 4.0” guidelines translate into real-world efficiency, the I-SENSE Group has released an explanatory video guide. The video demonstrates the automated extraction, control, and monitoring procedures that are setting new benchmarks for the industry. Watch the Video: https://www.youtube.com/watch?v=3e_yAvNZVpE

Learn more about MASTERMINE at https://www.mastermine-project.eu/